Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, although other conductive metals may be cut as well.

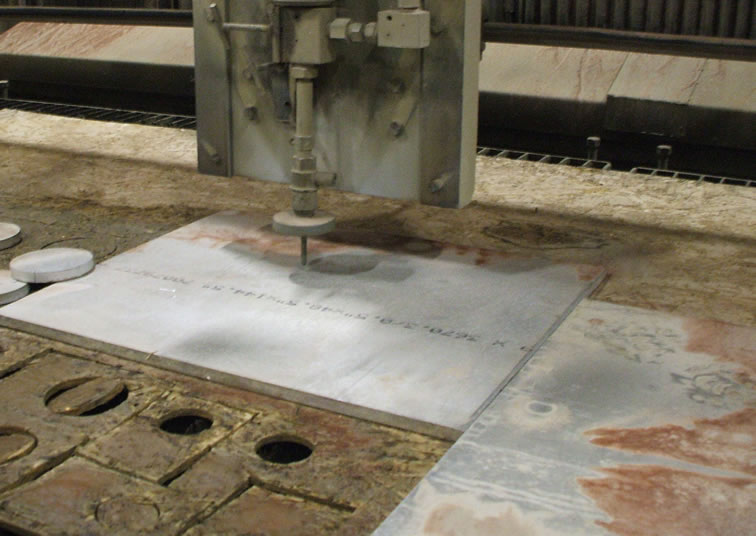

At Hatfield Metal Fabrication, we are capable of providing quality custom hi-definition waterjet cutting services, working with a variety of materials. We are qualified to handle many unique cutting needs required by our customers. Abrasive waterjet cutting utilizes a high velocity stream of water and abrasive that can be used to cut almost any material. Waterjet cutting cannot hold as tight a tolerance as wire EDM or CNC machining, although it is considerably more cost-effective for parts that do not require tight tolerances.

Hatfield Metal Fabrication is honored to have been directly involved in the manufacture of the wind chime memorial commemorating the lives lost in Shanksville, Pennsylvania on September 11, 2001.